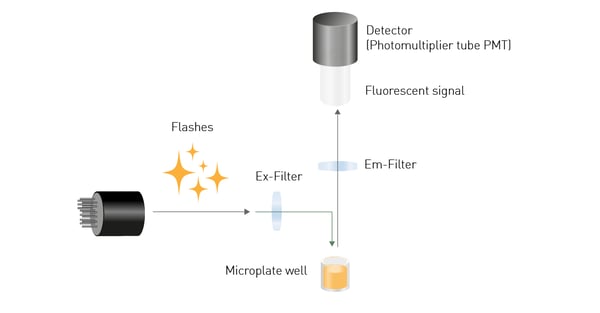

The ‘number of flashes’ is a setting that is typically displayed by microplate readers for all detection modes that require a light source. This includes fluorescence intensity and absorbance measurements. However, this setting is irrelevant in luminescence as an excitation light is not required for this type of measurement.

But how does the number of flashes influence your measurements and in which cases is a low or high flash number beneficial?

Your microplate reader will excite a sample with at least 1 flash per measurement, detect the emission and move on. If you select more than 1 flash in the settings, the corresponding number of detected emission signals will be averaged and displayed as one value. Although modern plate readers come with high flash frequencies, the time an instrument needs to measure a sample increases with the number of flashes used. This also has an influence on the total time needed to perform a measurement which is especially critical when performing fast kinetics with minimal time intervals between data point acquisitions. Accordingly, the defined number of flashes should be taken into consideration when performing kinetic experiments and adjusted

Your microplate reader will excite a sample with at least 1 flash per measurement, detect the emission and move on. If you select more than 1 flash in the settings, the corresponding number of detected emission signals will be averaged and displayed as one value. Although modern plate readers come with high flash frequencies, the time an instrument needs to measure a sample increases with the number of flashes used. This also has an influence on the total time needed to perform a measurement which is especially critical when performing fast kinetics with minimal time intervals between data point acquisitions. Accordingly, the defined number of flashes should be taken into consideration when performing kinetic experiments and adjusted

to a suitable level.

Did you know?

Flying mode is the fastest way possible to measure a plate. Different from the one flash measurement shown above, flying mode flashes once per well while the plate carrier is continuously in motion providing read times as low as 14 seconds.

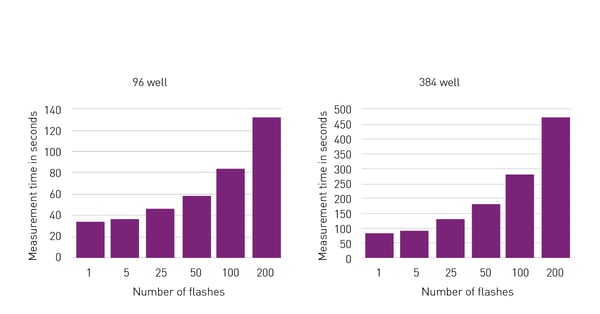

This example compares the total measurement times needed for full 96- and 384-well plates relative to the number of flashes used. The measurement time increases with the number of flashes used per measurement, regardless of the plate format used. However, with a higher number of measurement samples in smaller plate formats such as 384- and 1536-well plates the increase of total measurement time relative to the used number of flashes will be more impactful (e.g., 2-times increase between 50 and 200 flashes in 96-well versus 3-times increase in 384-well plates). Please note that measurement times also vary depending on reader model and manufacturer.

The overall number of flashes can also impact the excitation intensity of the light source. Xenon flash lamps used in BMG LABTECH microplate readers have a very long lifetime. Even after 100,000,000 flashes, they still maintain 50% of their emission intensity.

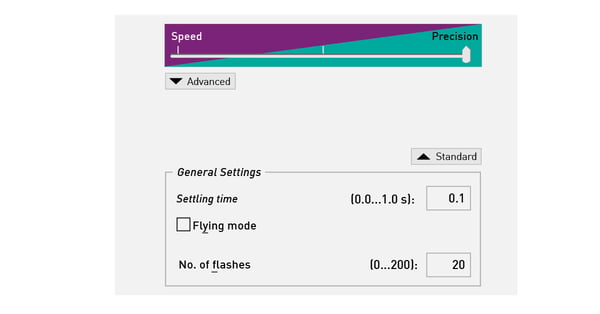

How to adjust the number of flashes on BMG LABTECH readers?

The number of flashes setting for a test protocol on a BMG LABTECH reader can be adjusted under the ‘manage protocols’

tab. Simply open the protocol you want to modify or create a new one. Now you can move the slider on the ‘Speed & Precision’ scale to one of three positions (fast, middle, and precise). By doing this, a recommended pre-set will be automatically selected. Alternatively, click on the “Advanced” button to adjust the number of flashes manually in a range from 0 to 200.

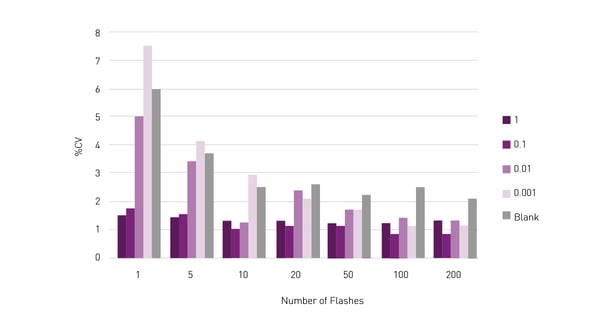

So why wouldn´t you always use the lowest possible number of flashes for your measurements and keep measurement time as low as possible? The answer is that this impacts your data variability! The microplate reader acquires the resulting emission signal after each additional flash. Detecting a sample with multiple flashes allows the microplate reader to form an average for each data point. This improves data stability and reduces variability originating from flash-to-flash variation. In particular, low concentration samples and blanks benefit from a higher number of flashes, as the reduced variability helps to decrease background noise (fig. 4).

Did you know?

If the time interval between data point acquisitions is too short, the BMG LABTECH control software will adjust it to the smallest interval setting possible to accommodate the selected flash number.

This example highlights the influence of the number of flashes on the coefficient of variation (%CV) values of a fluorophore standard series. While the %CV for high fluorophore concentrations down to 0.1 nM remained at low levels of 1-2 %, lower concentrations of fluorophore standard and blank samples depicted significantly higher variations. By increasing the number of flashes, the %CV of lower concentration standards and blanks could be reduced significantly. Using 10-20 flashes or higher resulted in %CV values around 3% or lower for all test samples.

Did you know?

BMG LABTECHs online library contains a huge variety of application notes which highlight the performance of

commonly used assays on our microplate readers and also provide recommendations for the reader settings, such as

number of flashes.

Using the highest possible number of flashes (e.g., 200) for every measurement is generally not recommended. After a given point, it will only artificially increase measurement time without further improving data quality. Moreover, it will decrease the lifetime of your light source. For many assays 10-50 flashes are sufficient. Higher settings might be beneficial for specific applications.

Conclusion

Selecting an appropriate number of flashes for your assay ensures reliable and accurate data. Not only does it help to keep coefficients of variation (%CV) and standard deviations low, but it also allows detection time to be reduced while prolonging the lifetime of the light source of your microplate reader.

Our Application Specialists Ann-Cathrin Volz, Ph.D. and Martin Mangold, Ph.D. further discuss the impact of different plate reader parameterson your data in the following video: How to Video: Get the best out of your microplate reader.